Smart Automation and Safety in Oil and Gas: The Axis Solutions Advantage

The oil and gas industry is undergoing a transformative shift towards increased safety, efficiency, and sustainability. By leveraging innovative smart automation technologies, companies are optimising operations, reducing costs, and enhancing environmental performance. Axis Solutions, led by Dr. Bijal Sanghvi, is at the forefront of this change, offering advanced automation solutions that empower the industry to meet modern challenges.

![[object Object]](https://admin.industrialautomationindia.in/storage/articles/article-TcxoWIltTEMIVqTj4KsOEMmkQQeja96cHErneYG2.jpg)

By leveraging innovative technologies in the field, oil and gas companies can enhance safety, efficiency, and sustainability, says Dr Bijal Sanghvi.

The oil and gas industry, a cornerstone of global energy production, is undergoing a significant transformation. This transformation is driven by the increasing need for safety, efficiency, and sustainability. Smart automation, a technology that leverages digital solutions to enhance operational processes, is emerging as a powerful tool to address these challenges. Axis Solutions, a leading provider of innovative solutions, is at the forefront of this technological revolution.

Axis Solutions' commitment to innovation and excellence has enabled them to develop cutting-edge smart automation solutions tailored to the specific needs of the oil and gas industry. By integrating advanced technologies such as artificial intelligence, and the Industry Internet of Things (IIoT), Axis Solutions empowers oil and gas companies to optimise their operations, reduce costs, and minimise environmental impact. With a focus on safety, reliability, and sustainability, Axis Solutions is driving the future of the oil and gas industry.

Present scenario of the oil and gas industry

The oil and gas industry is currently grappling with several key challenges:

- Declining Reserves: Conventional oil and gas reserves are dwindling, necessitating the exploration of unconventional sources like shale and deepwater. These unconventional resources often require advanced technologies and significant capital investments to extract.

- Price Volatility: Global economic conditions and geopolitical factors can lead to significant fluctuations in oil and gas prices. This price volatility makes it difficult for companies to plan for the future and invest in long-term projects.

- Stringent Regulations: Governments worldwide are imposing stricter environmental regulations to mitigate climate change. These regulations can increase operational costs and limit the industry's ability to expand.

- Safety Concerns: The industry faces inherent risks, including accidents, fires, and toxic gas leaks. These risks can have severe consequences for workers, the environment, and the industry's reputation.

- Talent Shortage: A shortage of skilled workers can impact operational efficiency and safety. As experienced workers retire and the industry evolves, there is a growing need for skilled professionals in areas such as engineering and project management.

Major applications of smart automation in oil and gas

Smart automation offers a wide range of applications to address these challenges:

- Remote Operations: Remotely operated vehicles (ROVs) and drones are revolutionising the oil and gas industry by enabling the execution of hazardous tasks in remote or inaccessible locations. These unmanned systems can perform a variety of operations, including underwater inspections, pipeline surveys, and well interventions. By minimising human exposure to dangerous conditions, ROVs and drones enhance safety and efficiency.

- Predictive Maintenance: By analysing sensor data collected from critical equipment, predictive maintenance techniques can identify potential equipment failures before they occur. This proactive approach allows for timely maintenance and repairs, reducing downtime, minimising operational disruptions, and extending the lifespan of assets. Predictive maintenance also helps optimise maintenance schedules and resource allocation.

- Enhanced Safety Systems: Smart Sensors and Automation Systems are playing a crucial role in improving safety in the oil and gas industry. These systems can detect potential hazards, such as gas leaks, fires, or equipment malfunctions, and trigger alarms or initiate automated safety protocols. By providing early warning and rapid response capabilities, these systems help prevent accidents and minimise their impact.

- Optimised Production: Automation technologies are transforming production processes in the oil and gas industry, leading to increased efficiency and reduced energy consumption. Automated systems can optimise operations, streamline workflows, and improve overall productivity. By minimising human error and maximising output, automation contributes to a more sustainable and cost-effective industry.

- Improved Decision-Making: Real-time data and advanced analytics provide valuable insights to inform strategic decision-making. By analysing vast amounts of data from various sources, such as production data, sensor data, and market trends, industry professionals can make informed decisions regarding exploration, production, and investment strategies. Data-driven insights help optimise resource allocation, mitigate risks, and enhance overall business performance.

The Axis Solutions advantage

Axis Solutions offers a comprehensive suite of smart automation solutions to help oil and gas companies overcome these challenges and achieve operational excellence:

- Advanced Automation Systems: Axis Solutions provides state-of-the-art automation products and systems that streamline operations, reduce human error, and enhance safety. These systems leverage cutting-edge technologies like artificial intelligence, and robotics to automate complex tasks and improve overall efficiency.

- IoT-Enabled Solutions: By integrating IoT devices, Axis empowers companies to collect and analyse real-time data from remote locations and to operate devices via the Internet, enabling remote monitoring and control. This connectivity enables predictive maintenance, optimised asset management, and improved decision-making.

- Cybersecurity Solutions: Axis prioritises cybersecurity to protect critical infrastructure and sensitive data from cyber threats. The products are compliant with the IEC 62443 standard, ensuring robust security measures. By implementing advanced cybersecurity solutions, Axis helps safeguard operations and maintain business continuity.

- Expert Consulting Services: Axis offers expert consulting services to help clients identify automation opportunities, develop implementation strategies, and optimise operations. The experienced consultants assess specific needs, recommend tailored solutions, and provide ongoing support throughout the implementation process.

Axis Solutions' product offerings for hazardous environments

- Analyser Shelters: Analyser shelters provide a controlled environment for sensitive instruments, ensuring accurate measurements and protecting them from harsh conditions such as extreme temperatures, humidity, and corrosive substances. These shelters are typically constructed from durable materials and equipped with climate control systems to maintain optimal operating conditions. By safeguarding critical instrumentation, analyser shelters contribute to the reliability and efficiency of oil and gas operations.

- E-houses/Porta Cabins: E-houses and porta cabins offer pre-fabricated, modular solutions for housing electrical and control equipment in hazardous areas. These structures are designed to meet stringent safety standards and provide a safe and secure environment for personnel and equipment. By consolidating electrical and control systems into a single, centralised location, e-houses and porta cabins improve operational efficiency and reduce maintenance costs.

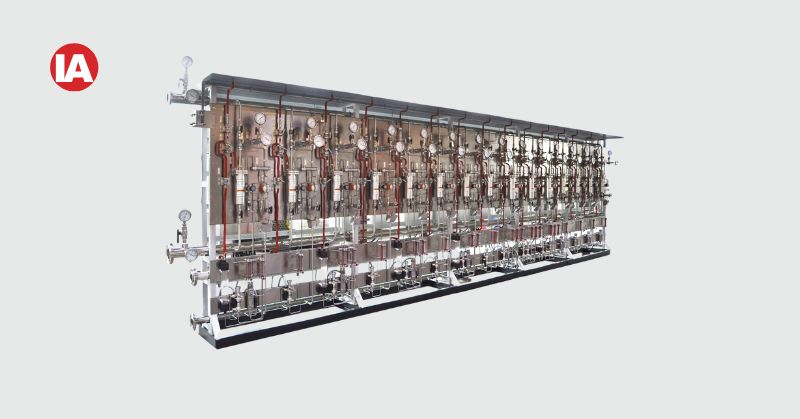

- SWAS and Smart SWAS: SWAS (Steam Water Analyser System) and Smart SWAS are advanced systems designed to monitor and analyse the quality of steam and water in various process applications. By continuously monitoring parameters such as conductivity, pH, and silica content, these systems help ensure optimal performance and efficiency. Smart SWAS systems, which integrate IoT and AI technologies, offer real-time monitoring, predictive maintenance, and optimised operations when connected remotely.

- Purge Panels: Purge panels maintain a positive pressure of inert gas to prevent the entry of flammable gases and protect equipment. These systems are essential for ensuring the safety of personnel and equipment in hazardous areas. By purging the atmosphere with an inert gas, purge panels reduce the risk of fire and explosion.

- Ex-Proof ACs: Ex-proof ACs are specially designed air conditioning systems that are safe for use in hazardous areas. These units are certified to meet stringent safety standards and are equipped with explosion-proof components to prevent the ignition of flammable gases. By providing a comfortable working environment, ex-proof ACs improve productivity and reduce fatigue.

- Process Packages: Customised process packages tailored to specific needs, including instrumentation, control systems, and safety systems. Process packages are customised solutions tailored to specific needs, including instrumentation, control systems, and safety systems. These integrated packages provide a comprehensive approach to process automation, optimising performance and reducing operational costs. By combining hardware and software components, process packages offer a flexible and scalable solution for a wide range of applications.

Addressing sustainability and agility challenges

Axis Solutions' smart automation solutions also contribute to sustainability and agility in the oil and gas industry:

- Reduced Carbon Footprint: By optimising operations and reducing energy consumption, smart automation can significantly minimise the industry's carbon footprint. Advanced technologies such as AI and machine learning can analyse vast amounts of data to identify inefficiencies and optimise resource utilisation. This leads to reduced greenhouse gas emissions and a smaller environmental impact.

- Enhanced Environmental Performance: Automation can help improve environmental performance by reducing emissions and minimising waste. For instance, automated systems can monitor and control emissions levels, ensuring compliance with environmental regulations. Additionally, predictive maintenance can reduce equipment failures and minimise the release of hazardous substances.

- Improved Safety: By reducing human intervention in hazardous tasks, smart automation can significantly improve safety and reduce accidents. Remote-controlled vehicles and drones can perform risky operations in challenging environments, minimising the risk to human life. Moreover, automated systems can detect potential hazards and trigger alarms, enabling timely response and preventing accidents.

- Increased Agility: Smart automation enables faster response to market changes and regulatory requirements. By automating routine tasks and streamlining workflows, companies can adapt quickly to evolving market conditions. Additionally, advanced analytics can provide real-time insights, empowering businesses to make data-driven decisions and respond promptly to changing circumstances.

Conclusion

By leveraging Axis Solutions' innovative technologies in the field of Analytical, Instrumentation, and Automation Products and System Solutions, oil and gas companies can enhance safety, efficiency, and sustainability, ensuring a more resilient and sustainable future. Axis Solutions' cutting-edge solutions empower oil and gas companies to streamline operations, reduce downtime, and maximise production through advanced automation and digitalisation. Robust safety systems, including predictive maintenance and remote monitoring, minimise accidents and protect personnel. Additionally, the reduction of emissions, conservation of energy, and minimisation of waste through sustainable practices and technologies contribute to improved environmental performance. Real-time data and analytics provide valuable insights, optimise resource allocation, and enhance decision-making. By embracing emerging technologies and industry trends, oil and gas companies can stay ahead of the curve and ensure long-term success.

Dr Bijal Sanghvi is the Managing Director of Axis Solutions Pvt Ltd, a distinguished first-generation company having a Domestic as well as Global Presence, which has achieved remarkable milestones. His role spans across various verticals ranging from managing the overall development and operations of the firm with leadership roles across business strategy, business development and management of various business functions such as Production, Engineering, Manufacturing and R&D.

_____________________________________________________________________________________________

For a deeper dive into the dynamic world of Industrial Automation and Robotic Process Automation (RPA), explore our comprehensive collection of articles and news covering cutting-edge technologies, robotics, PLC programming, SCADA systems, and the latest advancements in the Industrial Automation realm. Uncover valuable insights and stay abreast of industry trends by delving into the rest of our articles on Industrial Automation and RPA at www.industrialautomationindia.in