Online Continuous Emission Monitoring System

Discover how regular testing and standards like EN 14181 ensure the reliability and sustainability of Continuous Emission Monitoring Systems (CEMS). Go beyond QAL-1 certification with QAL-2 and Annual Surveillance Tests (AST) to maintain compliance, reduce downtime, and support environmental sustainability.

Ensuring reliability, validation, and sustainability of Online Continuous Emission Monitoring System (OCEM).

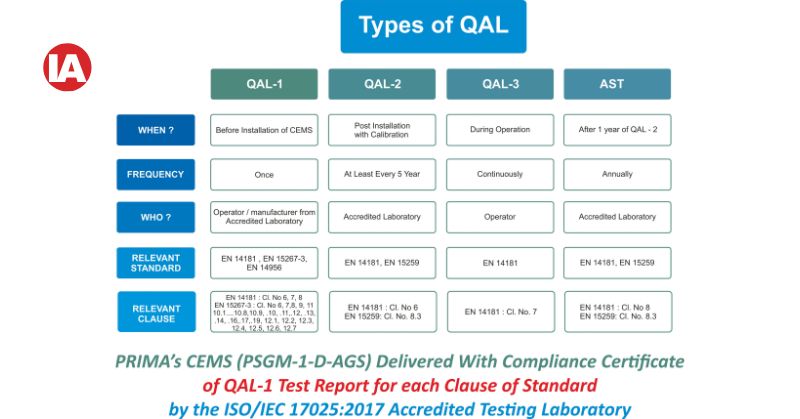

Continuous Emission Monitoring Systems (CEMS) are vital for maintaining environmental compliance by ensuring industrial emissions stay within regulatory limits. While obtaining a QAL-1 Testing or certificate for your installed CEM system is a significant milestone, relying solely on this certification is insufficient for ensuring long-term performance and compliance. Regular testing and adherence to standards like EN 14181 and EN 15267-3 are essential for maintaining the system's reliability, validation, and sustainability.

The importance of regular testing and certification

1. Continuous Performance Reliability: A QAL-1 Test report/certificate signifies that a CEM system met certain performance standards at the time of testing. However, over time, factors such as wear and tear, environmental conditions, and operational variations can affect the system’s performance. Regular testing, particularly as per QAL-2 and Annual Surveillance Test (AST) protocols, ensures that the system continues to operate reliably and within the specified parameters.

2. Validation and Compliance: EN 14181 and EN 15267-3 standards provide a framework for the validation and ongoing performance verification of CEMS. These standards require initial testing/certification (QAL-1), periodic quality assurance tests (QAL-2), and annual surveillance tests (AST). Compliance with these standards ensures that the system not only meets initial certification requirements but also continues to provide accurate and reliable data over its operational life.

3. Sustainability: Regular testing and validation contribute to the sustainability of a CEM system by identifying and addressing potential issues before they lead to significant failures. This proactive approach reduces downtime, maintenance costs, and environmental impact, ensuring that the monitoring system remains effective and sustainable in the long run.

Key components of comprehensive CEM system testing

1. Initial Testing/Certification (QAL-1): The first step in ensuring a reliable CEM system is obtaining initial testing/certification of all test clauses according to EN 14181. This involves rigorous testing to verify that the system meets performance standards.

2. Periodic Quality Assurance Tests (QAL-2): QAL-2 involves regular testing to ensure the CEM system continues to perform accurately over time. This includes calibration and functional checks to identify and rectify any deviations.

3. Annual Surveillance Tests (AST): ASTs are conducted annually to verify that the system maintains its QAL-1 Test performance levels. This ongoing surveillance helps in early detection of potential issues and ensures continuous compliance with regulatory standards.

Conclusion

While a QAL-1 Testing is an important step in the performance of a CEM system, it is not sufficient to guarantee long-term reliability, validation, and sustainability. Regular testing and compliance with standards like EN 14181 and EN 15267-3 are crucial for ensuring the system’s ongoing performance and compliance. By adhering to these standards and conducting regular QAL-2 and AST tests, companies can ensure their CEM systems provide accurate, reliable, and sustainable environmental monitoring over their operational life.

Investing in comprehensive and ongoing validation and testing not only ensures compliance but also enhances the overall sustainability and reliability of environmental monitoring systems.

Furthermore, statutory bodies should incentivise companies to maintain their Continuous Emissions Monitoring Systems (CEMS). These systems are often perceived as non-productive, and can suffer from low maintenance, leading to faulty data. Proper incentives, like tax breaks or grants, can encourage better upkeep, resulting in more accurate environmental monitoring and compliance with regulations.

For more information write us at info@primaequipment.com

____________________________________________________________________________________________

For a deeper dive into the dynamic world of Industrial Automation and Robotic Process Automation (RPA), explore our comprehensive collection of articles and news covering cutting-edge technologies, robotics, PLC programming, SCADA systems, and the latest advancements in the Industrial Automation realm. Uncover valuable insights and stay abreast of industry trends by delving into the rest of our articles on Industrial Automation and RPA at www.industrialautomationindia.in